Where did my bike come from?

And is it titaaaaniiiiuuuum?

Until recently, I shared an office with Sustrans, a charity that promotes the use of sustainable modes of transport – chief among them, bicycles. In an impressive display of dogfooding, their section of the building looked like a showroom for Bromptons, those little folding bikes that have developed a cult following and become a great success story for British design and engineering. (For more on the company’s history, check out last year’s book by Brompton CEO Will Butler-Adams and Dan Davies off Twitter.)

Faced with a slightly longer commute to Data Desk’s new office, I finally accepted my status as a Millennial yuppie NPC and bought a second-hand one last week. And of course I love it – it rides beautifully, it’s easy to fold up and, crucially, it’s light enough to carry up and down stairs on the Overground or at the office. The key to this lightness is titanium, a metal that makes me think more than anything of French dance music, but which it turns out has some very useful properties – and a tricky supply chain.

For a primer on the global titanium industry, check out Paul Chapman’s conversation with Taso Arima, CEO of US-based titanium company IperionX, on the HC Insider podcast. Arima has skin in the game, so his narrative should be taken with a pinch of salt, but he explains how titanium and its alloys offer a better strength-to-weight ratio than steel while being more corrosion-resistant too, making them ideal for subsea applications like tidal turbines. IperionX aims to reduce the carbon intensity of titanium production, so it can be more suitable for use as a key material in the energy transition.

But there’s another, by-now familiar problem for companies seeking to use titanium: disruption to global supply chains caused by the pandemic and the war in Ukraine.

More than for bikes, titanium is a key component for modern aeroplanes. According to Department of Commerce data, orders for civilian aircraft in the United States jumped by 115% between November and December 2022 as the post-pandemic rebound in air travel pushed airlines to upgrade or expand their fleets, a trend which has created massive demand for aerospace-grade titanium. To make matters worse, the world’s largest producer is VSMPO-AVISMA, a company not only based in Russia but a subsidiary of the country’s state-owned defence conglomerate Rostec.

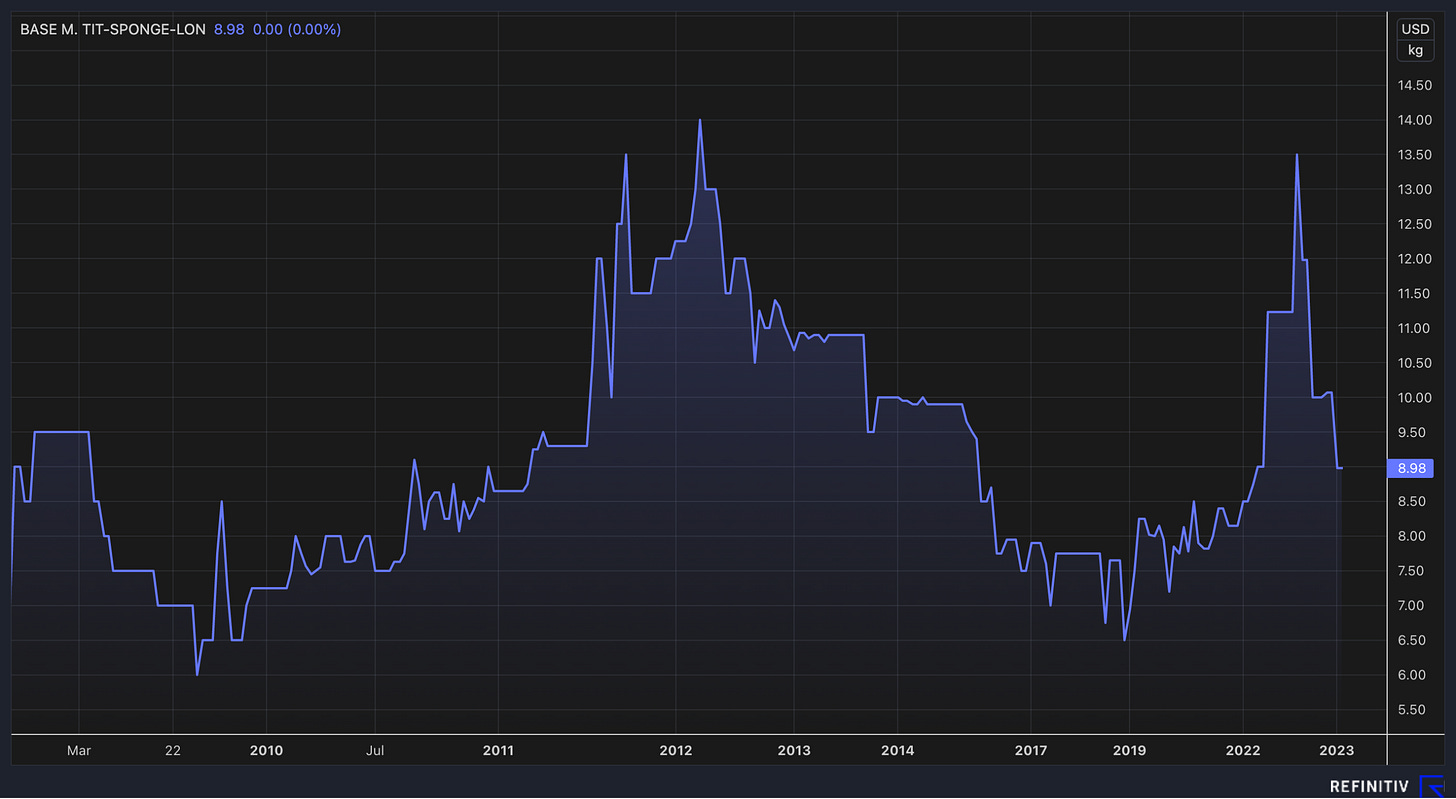

The titanium trade is relatively opaque, made up of long-term contracts between producers and consumers, but Refinitiv provides some spot price estimates. A major one is for titanium sponge (an intermediate form of the metal which is the most commonly traded) delivered to north-west Europe, which more than doubled in price between the beginning of 2019 and mid-2022, reaching levels not seen for a decade.

How bad is all this for the good people at Brompton Bicycles? My bike is second-hand and according to the serial number was built in 2012, when peace prevailed in Europe and Brompton used a Russian manufacturer for the main titanium component, the ‘rear triangle’ that holds the back wheel. Will Butler-Adams’s account of the deal in his book with Dan Davies is worth quoting at length:

This was not at all a comfortable thing to do. The business press was full of stories of people getting ripped off in the chaotic legal system of Russia. I had met the owner of Rapid, drunk vodka with him and all that, and I liked him, but how much did we really know about him and the company? And how much did we know about the people who were meant to be supplying the titanium? Andrew and I discussed this for some while, before basically talking each other into a rush of adrenaline and sending the bank transfer. At that precise moment, we couldn’t be sure whether the material for our frames had even been dug out of the ground. But Rupert and his team were as good as their word – our trusting nature was rewarded and we were able to start listing the Superlight models in 2006.

Even though Brompton has since established a joint venture with CW Fletcher, a Sheffield-based components supplier for the aerospace and nuclear industries, according to the FT the raw material still comes from Russia, China or Ukraine. And as Butler-Adams recently admitted, “[t]hat restriction in supply out of Russia and Ukraine means that more people are going to China, the price of titanium is going up. So yes, that is a risk.” All of this makes it an interesting (read: terrible) time to launch an all-titanium model – which perhaps explains why it costs more than £4,000.

I look forward to a day when more of the vast natural, capital and human resources of Russia’s post-Soviet industrial economy are turned where the world needs them: towards manufacturing for a decarbonised economy rather than continued extraction of fossil fuels and production of military hardware. Until then, the Brompton – Buccaneering Britain’s signature export – is a reminder of how integrated the economies of East and West have become, and how much there is still to be pulled apart.